Key Points

- Freepoint Eco-Systems plans a 44-acre plastic recycling facility in the Eloy Industrial Park to convert 400 million pounds of waste plastic per year into recycled oil and gas.

- The company estimates the project would create more than 100 jobs, generate $19 million in tax revenue over 10 years, and require $300 to $400 million in capital investment.

- A constituent provided board members with documentation of multiple air quality violations at Freepoint’s existing Ohio plant, including Notices of Violation from the Ohio EPA for visible emissions, unpermitted venting, and equipment malfunctions.

- The air quality permit modification is in a public comment period through March 9, 2026. A public hearing is scheduled for that date, and the draft permit is available for review.

- The Board of Supervisors has no approval authority over the facility. The City of Eloy approved the site plan in December 2025.

A 44-acre plastic recycling facility planned for the Eloy Industrial Park was the subject of a Pinal County Board of Supervisors work session on Feb. 11, 2026. Freepoint Eco-Systems, the company behind the project, plans to convert roughly 400 million pounds of waste plastic per year into recycled oil and gas. According to the company, the facility would bring more than 100 permanent jobs to the area and generate an estimated $19 million in property tax revenue over 10 years. The company’s chief development officer, Geof Storey, estimated the project would require roughly $300 to $400 million in capital investment. However, air quality violations documented at the company’s existing Ohio plant have raised questions from at least one community group.

The work session was informational only. No vote or board action was required. The City of Eloy approved the project’s site plan in December 2025. Pinal County’s sole involvement is an air quality permit.

How the Facility Would Affect the Eloy Industrial Park

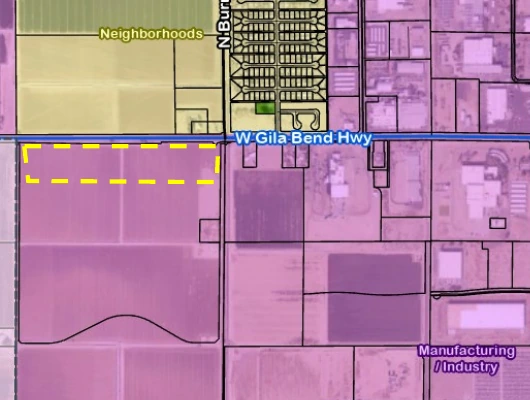

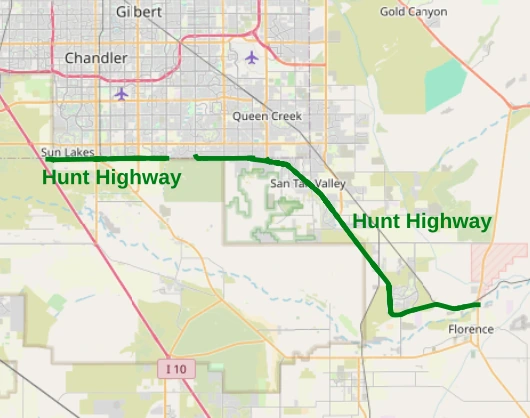

Freepoint plans to build its facility at the southeast corner of Battaglia Road and Interstate 10 in the Eloy Industrial Park. The site sits between Phoenix and Tucson along the I-10 and I-8 corridor, directly on the Union Pacific rail line.

The company chose this location to serve as its southwest hub. Storey said the company expects to collect waste plastic from across the Southwest, including from Southern California, Las Vegas, New Mexico, and potentially as far as Denver, along with the Arizona market. He said the company liked the Eloy site because of “its location directly on the U.P. line, because we have to ship all that oil back to the Gulf Coast.”

Beyond the plant itself, Storey said Freepoint plans to install new roads in the industrial park and upgrade the Union Pacific mainline. Both improvements would benefit other industrial customers in the park, he said.

What the Plant Would Do

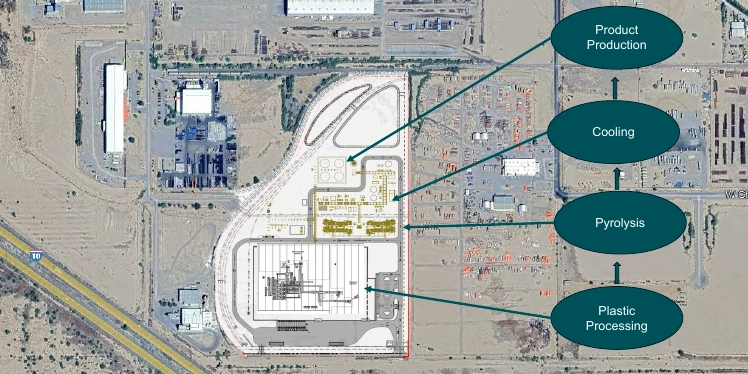

During his presentation, Storey described how the facility would operate. Freepoint takes waste plastic and converts it back into oil and gas through a process called pyrolysis. That recycled oil is then sold to petrochemical companies such as Dow Chemical, DuPont, LyondellBasell, and Exxon Chemical. Those customers use it to manufacture new plastic products.

The process works inside a rotary kiln that heats plastic in the absence of oxygen. “We’re just trying to degrade it back down into oil and gas,” Storey said.

The reactor produces a hot hydrocarbon vapor containing a range of products from natural gas to gasoline to heavy oils. The lightest hydrocarbons, such as methane and ethane, are recycled to heat the kiln itself. Roughly 10% of the plastic serves as fuel for the process. The rest is condensed into liquid oil, loaded onto rail tanker cars, and shipped to customers primarily on the Gulf Coast.

Additionally, about 5% to 6% of the reactor output is a carbon black byproduct the company calls “char.” That material is disposed of separately.

Storey said most waste plastic feedstock will arrive by truck. All product will leave by rail.

The proposed Eloy facility would be roughly double the size of Freepoint’s existing plant in Hebron, Ohio. According to the company, that 25-acre facility has been operational since March 2025 and currently ships recycled oil via rail to Shell Chemical. It employs more than 100 people and processes about 175 million pounds of waste plastic per year.

Storey said: “That’s a pound of plastic that didn’t need to go into landfill, and that’s a pound of oil that didn’t need to be drilled for and sent to the petrochemical complex.”

Where the Waste Plastic Comes From

Storey described the company’s raw material as coming from several sources. Roughly a third comes from material recovery facilities (MRFs), he estimated, and the company plans to contract with MRFs in Phoenix, Tucson, and Las Vegas. Another third or so comes from other recyclers. For example, plastic bottle recyclers produce labels and caps that cannot be mechanically recycled. Paper recyclers generate plastic residue streams. Freepoint acquires all of that material.

The remaining third comes from manufacturers and other industrial sources, Storey said. He cited pill bottles as one example. When pharmacies like Walgreens dispose of unclaimed prescriptions, the leftover bottles go to document destruction companies for shredding due to patient information. Those shredded bottles typically go to landfills, but Freepoint acquires them instead. Packaging trim waste from manufacturers is another common source.

Chairman Jeff McClure asked whether Freepoint would accept mixed, contaminated recyclables directly from haulers. Storey said it would not. “We will not be shipping any municipal solid waste to Eloy to sort through that,” he said. “That’s too unprofitable. There’s not enough plastic in it. It’s highly contaminated.”

Residents’ blue bin recyclables would not go directly to this facility. Those curbside materials first go to MRFs for sorting. Freepoint then buys specific plastic streams from those MRFs after the initial sorting is complete.

Sorting Plastics at the Facility

Inside a proposed 320,000-square-foot warehouse, workers and equipment would sort incoming plastic into material suitable for the reactor. The company spends about a third of its money on sortation and contamination cleanup, according to Storey. The sorting process uses near-infrared optical scanners on high-speed conveyor belts to identify plastic types, then compressed air jets separate targeted plastics from residue.

Storey said the company specifically removes contaminants such as PVC, metals, paper, and flame-retardant plastics before material enters the reactor.

Raw Material Costs and the Business Model

Vice-Chairman Jeff Serdy questioned whether residents benefit from the arrangement, comparing the model to organizations like Goodwill that receive goods for free and profit from reselling them.

Storey responded that Freepoint does not need public support or incentives. “There’s 36 million tons a year of waste plastic,” he said. According to Storey, most of what the company acquires comes from parties trying to avoid landfill costs. In many cases, the company pays little or nothing for the material, and it focuses on finding the cleanest, least contaminated material it can process efficiently.

Economic Impact and Tax Revenue

Much of that capital investment covers equipment. Supervisor Stephen Miller noted that personal property tax on that equipment, combined with the assessed value of the real property, is where the bulk of tax revenue comes from.

The company’s presentation also cited $1.04 billion in projected economic output in the region over the 10-year period, along with more than 100 direct jobs, over 200 indirect jobs, and 250 construction jobs.

Sales Tax Discussion

Serdy also asked why no sales tax would be collected on the product Freepoint sells. Storey noted the product is sold wholesale. County Manager Leo Lew confirmed that manufacturers selling wholesale generally do not pay the privilege tax on their product. Instead, the tax is collected further down the supply chain when the product eventually reaches the end consumer. Serdy confirmed his understanding that sales tax would ultimately be collected when the recycled material is made into a finished product and sold at retail.

Air Quality Permit and Regulatory Authority

The Pinal County Air Quality Control District is the governing permitting authority for this facility. The Arizona Department of Environmental Quality delegated permitting and enforcement responsibilities within Pinal County to PCAQCD.

Freepoint received its original air permit in December 2021. In November 2025, Storey said the company submitted a permit modification based on its experience operating the Ohio plant. He said the modification includes recovery of a wider range of products. According to the company’s presentation, it also adds recordkeeping and reporting requirements to demonstrate that more than 70% of input plastic is recycled, and results in a decrease in total volatile organic compound emissions. According to PCAQCD’s public notice, the public comment period on the modification opened Feb. 5, 2026, and closes March 9. A public hearing is scheduled for March 9 at 10 a.m. The draft permit is available on the county’s website.

According to the company’s presentation, the facility holds a Class II Minor Source Air Permit with all emissions below the Title V Major Source threshold. Permit conditions include the use of control devices, throughput limits, and emissions caps. In a separate agenda item at the same work session, the board heard a proposal to tie air quality permit fees to the Consumer Price Index across all permit classes, including Class II.

Planning Manager Harvey Krauss confirmed that the Board of Supervisors has no approval authority over the facility itself. It sits within the corporate limits of the City of Eloy. The county’s only involvement is the air quality permit.

Why the Work Session Happened

Supervisor Miller opened the meeting by taking responsibility for the agenda item. He said a constituent had approached him about the project while he was serving as board chairman. Miller told the constituent there would be an opportunity to discuss the project before the board. He later acknowledged he had misspoken about the nature of that opportunity.

Deputy Chief of the Civil Division Christine Roberts explained that work sessions are designed for staff to give updates and seek guidance from the board. “It is not an opportunity for public discussion,” she said. “There is no call to the public.” Roberts said staff and invited presenters could address the board, but not the general public.

Miller said that Ralph Atchue, the constituent, had provided a handout that would be distributed to board members after the meeting.

Concerns Raised in Atchue’s Handout

The handout, prepared by Kevin Greene of the group Stop Waste Tucson, documented a series of air permit violations at Freepoint’s existing Hebron, Ohio plant. It cited the following incidents:

In October 2024, the Ohio EPA visited the Hebron facility in response to a dust complaint. Inspectors found that Freepoint was operating raw material processing equipment — including five shredders, sorting operations, and associated conveyors — without the required air pollution permits. The agency issued a Notice of Violation and directed the company to submit a compliance plan within 30 days.

In February 2025, community members captured video of dark smoke from the facility’s stacks. The Ohio EPA inspected on Feb. 13, 2025, and later issued a Notice of Violation for visible particulate emissions exceeding the 20% opacity limit.

During the summer of 2025, the facility reportedly exceeded permitted particulate matter limits, resulting in additional compliance notices.

Between February and June 2025, Freepoint disclosed 79 separate occasions when volatile gases were vented to an unpermitted flare rather than the required vapor combustors. Some events lasted up to 59 hours.

In November 2025, the Ohio EPA issued another Notice of Violation citing the unpermitted venting. Community sources characterized this as the third air permit violation within approximately one year.

During the first two weeks of December 2025, Ohio EPA inspectors observed visible emissions exceeding particulate limits on four separate dates. The company reported pollution control equipment malfunctions from Dec. 2 through Dec. 15 but did not immediately notify the Ohio EPA as required. The facility was also cited for using an unpermitted hydrochloric acid control system and for failing to conduct mandatory emissions testing for both HCl and particulate matter.

The handout also detailed broader concerns about the pyrolysis industry, including operational instability and questions about long-term profitability. It cited four U.S. thermal recycling facilities that have closed: Regenyx in Oregon, New Hope Energy in Texas, Fulcrum BioFuels in Nevada, and Renewlogy in Utah.

Safety Questions About the Ohio Plant

Supervisor Rich Vitiello asked what would happen if oxygen entered the reactor. Storey acknowledged that oxygen intrusion in a high-temperature environment would cause combustion. “If you had complete uncontrolled air, that’s a catastrophic accident if that happened,” he said. He added that the company conducts hazard studies and uses dual fail-safes.

Vitiello then asked whether anything like that had occurred at the Hebron facility. Storey said it had not. “Have we had oxygen intrusion into the reactor? No,” he said. He acknowledged the company has made mistakes but confirmed no such incident had taken place.

“Just trying to make sure we protect our citizens, that’s all,” Vitiello said. Storey said he personally spends time at the Ohio plant and wants to be protected as well.

Myths and Facts About Advanced Recycling

During his presentation, Storey addressed several claims commonly made about the pyrolysis process. These points appeared in both his remarks and the company’s slide deck.

Pyrolysis is not incineration. If the company burned the plastic, it would have no product to sell. Storey said the Pinal County Air Quality District, the Ohio EPA, and the Arizona DEQ have all determined Freepoint is not a waste combustor and should not be regulated as one.

Post-consumer waste can be suitable for pyrolysis after sorting. Unsorted waste is unsuitable. As described above, Freepoint dedicates significant resources to sorting and contamination removal before material enters the reactor.

Oxygen intrusion is a real risk the company designs against. As Storey described during board questioning, the facility uses hazard studies and dual fail-safes to prevent air from entering the reactor.

Pyrolysis creates petrochemical feedstock, not just fuel. The company’s ISCC certification, which it has held since 2022, is designed to ensure the recycled hydrocarbons are directed back to petrochemical customers for manufacturing new products. However, Storey acknowledged that once the product is sold, customers “can do whatever they want with it.”

Advanced recycling is a relatively new industry that is still scaling. Storey acknowledged that other companies have tried and failed. However, he said Freepoint is making the process work in Ohio and delivering product to customers. He noted that Pinal County benefits from being a “second mover,” meaning the company will only build the Eloy plant if the Ohio facility continues to succeed.

Public Awareness and Future Timeline

At the close of the work session, Vice-Chairman Serdy addressed the audience directly. “So the public knows, this is happening,” he said. “There’s no vote on this or anything. We’re just for information to let the people know what this plant will be doing and why.”

The public comment period on the air permit modification closes March 9, 2026. According to the company’s presentation, outstanding items with the City of Eloy include a parcel combination and building permit. No future Board of Supervisors votes are scheduled on the project.